How it works

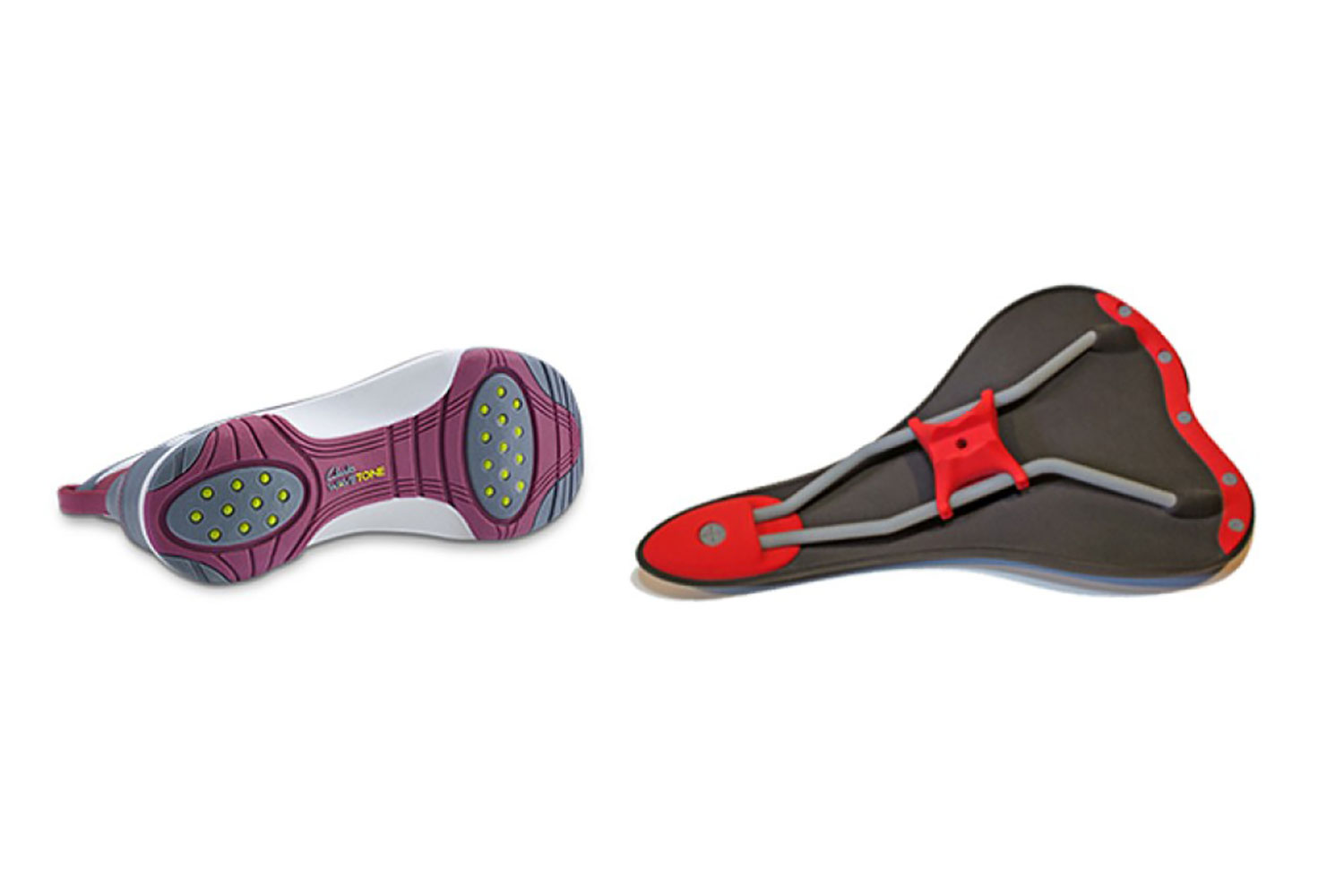

Colorjet is the major 3D printing technology to create full-color parts. Full-color plaster can be printed with more than 360,000 colors, at a layer height of only 0.1 mm – the results are stunningly realistic, fully-colored 3D printed parts. Since no support structures are required during printing, even very complex shapes can be realized. Full-color plaster is mainly used for design prototypes, architectural models, science & education, art, fantasy and merchandise products.

The Process

| Pre-processing: | Production: | Post-processing: | The 3D CAD model of a part or component is oriented, sliced and posited using special control software. This software translates the 3D data into two dimensional layers corresponding to the part geometry while also adding any support structures needed to successfully print the model. | ColorJet Printing technology involves two major components – core and binder. The material is spread in thin layers over the build platform with a roller. After each layer is spread, color binder is selectively jetted from inkjet print heads over the core layer, which causes the material to solidify. The build platform lowers with every subsequent layer which is spread and printed, resulting in a full-color three-dimensional model. Full color 3D Printing is ideal for creating full color concept models and demonstration models. | After successful printing, the model is still soft and fragile. The model is carefully cleaned in this semi-finished state and finally infiltrated with an acrylic compound (commonly known as ‘super glue’). This infiltration provides the model’s strength. In our Premium Finishing process, models go through two additional steps of surface enhancement after infiltration. |

|---|

Advantages

Advantages

-

- Cost efficient technology

- No support structures necessary

- Capable of printing in an extremely wide range of colors

- Parts can be clear coated to add a hard, smooth coating or wax coated to smooth out the surface finish

Limitations

Limitations

- Brittle, low mechanic strength

- Cannot be used for functional prototypes, since abrasion is too high and the material breaks easily

- Not water-resistant